Many homeowners take pride in keeping their pool pristine but underestimate the importance of balancing the swimming pool’s water chemistry. Further, few people are aware of its potential impact on stainless steel parts in integrated pool covers or SwimJets.

Ensuring your swimming pool’s water chemistry is in balance is the best way to minimise corrosion and maximise longevity. This article will delve into the key reasons to balance your swimming pool water chemistry, including:

- Preventing corrosion and staining of stainless steel

- Ensuring your pool cover operates at an optimal level

- Maintaining the look of your pool environment

- Protecting your family

The Science Behind Swimming Pool Water Chemistry

Pool water may appear calm and clear, but it is a dynamic environment. In fact, its influenced by various factors, such as rain, salt, chemicals and swimming.

If the water chemistry is imbalanced, it can become either too acidic (low pH) or too basic (high pH). Neither is ideal for swimmers’ health, the pool’s finish, or the integrated stainless-steel components.

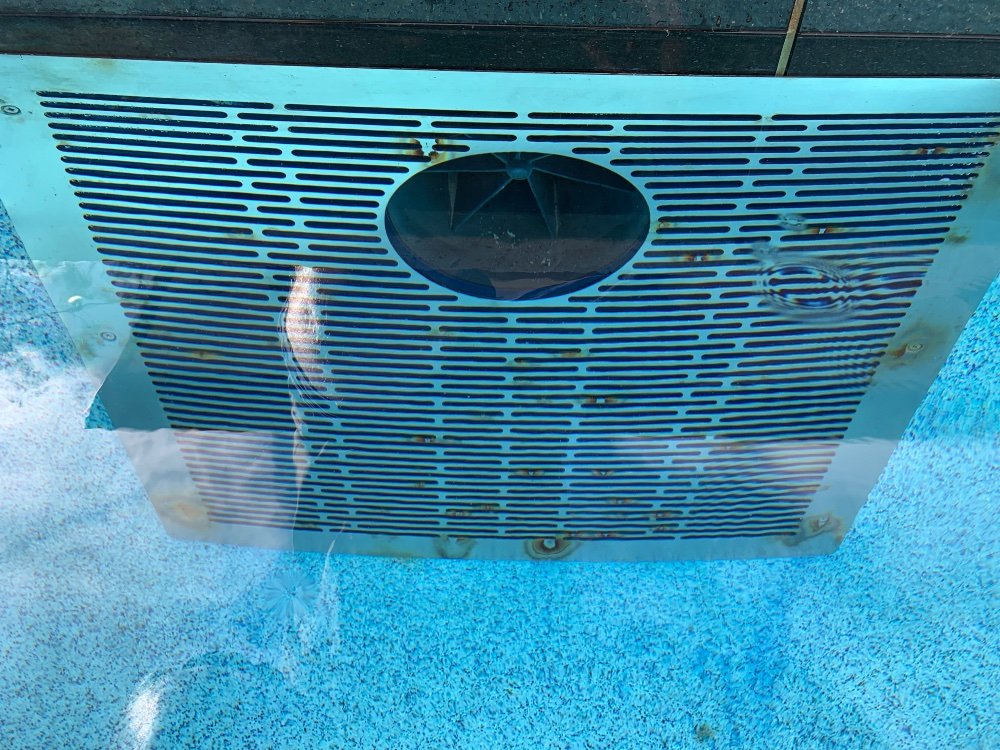

Acidic water with low pH can corrode the stainless-steel surface, forming tiny holes on the metal surface called pitting. Over time, pitting can weaken the metal surface. On the other hand, alkaline water with high pH can cause staining of stainless-steel parts, affecting functionality and aesthetics.

Chlorine is often added to pools to sanitise the water, but high chloride levels can be corrosive to stainless steel. Chlorides can form a concentrated salt solution in these areas, which can corrode stainless steel over time.

Imbalanced salt in the water can also impact stainless steel by creating rust stains or adding to corrosion.

The impact of Water Chemistry on Stainless Steel Components

The Power of Prevention

Even the most robust materials can wear when exposed to imbalanced water chemistry. By maintaining proper water balance, you actively protect these components from corrosive elements.

Balanced water chemistry protects your investment and maintains its appearance. This in turn ensures you don’t have to replace parts frequently and can enjoy your pool cover for years.

Optimal Performance

Imbalanced water can corrode the surface of stainless-steel parts, hindering the pool cover’s operations and causing it to break down.

Ensuring the proper chemical balance is like providing your pool cover with the best environment to perform at its peak. Like other machinery, smoother operations will result in less wear and tear in the long run.

Maintaining Aesthetics

If pool cover components begin to corrode or develop stains, their allure can quickly fade.

The beauty of stainless steel is best preserved in a balanced aquatic environment. This ensures functionality and safeguarding your pool area’s aesthetic appeal.

Safety

When the stainless-steel components of your pool cover are compromised, so is its ability to provide protection.

Corrosion or any other damage can weaken the cover’s structure, making it less reliable. By ensuring balanced water chemistry, you’re directly reinforcing the safety of your pool area. A safer pool environment provides peace of mind for you and your loved ones.

Steps to Maintain Balanced Water Chemistry

- Regular Testing. Purchase a high-quality water testing kit and check your pool’s pH, chlorine, and total alkalinity levels. This should be conducted at least once a week.

- Adjust Chemicals as Needed. Based on your test results, adjust the levels of chemicals to bring them into the recommended range.

- Clean the Pool. Regularly remove leaves, debris, and algae. This not only keeps the water clear but also prevents additional chemical imbalances.

- Keep an Eye on Chloride Levels. While chlorine is essential for sanitation, ensure it remains within the recommended range.

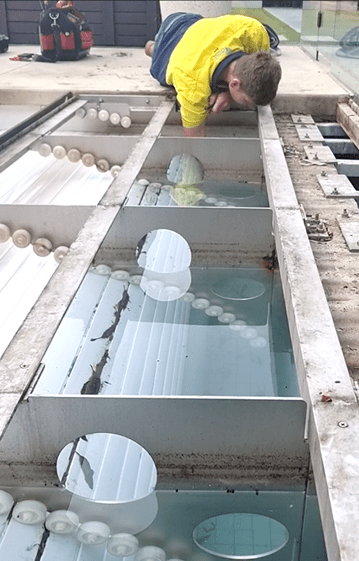

- Consult Professionals. Periodically, it might be beneficial to consult with a pool professional to evaluate your pool’s water chemistry and provide guidance.

Remco’s Recommended Water Chemistry Ranges

To prevent staining and corrosion of the stainless-steel components in the pool, it is of utmost importance that the pool water chemistry is maintained within what is considered safe and acceptable levels for salt, chlorine and pH in domestic swimming pools.

| Impact on Stainless Steel | |||||

| Parameter | Acronyms | Safe range for swimming | Midrange | Over Max | Under Min |

| Salt | N/A | 2700 – 3400ppm | 3050ppm | Staining/ Corrosion | No Impact |

| Chlorine | FCL/TCL | 1.0 – 3.0ppm | 2.0ppm | Staining/ Corrosion | No Impact |

| pH | N/A | 7.2 – 7.8 | 7.5 | No Impact | Staining/ Corrosion |

| Alkalinity | ALK/ALKY | 120 to 160ppm | 140ppm | No Impact | Staining/ Corrosion |

Remco advises our customers to keep the levels at the lower end of these ranges. We do this as it provides scope for upward fluctuation should levels increase.

Maintenance at the mid-range is also workable as it provides scope for increases should they occur. For instance, the salt range is between 2700-3400 ppm, and maintenance midway through this range (i.e. 3050 ppm) would be acceptable.

Regarding chlorine, where the range is between 1.0 and 3.0 ppm, maintenance midway through this range would also be acceptable. For pH, where the safe range is between 7.2 & 7.8, maintenance at 7.5 is workable.

We also recommend regularly wiping exposed stainless-steel surfaces to prevent a build-up of any impurities.

Remco’s Preventative Maintenance Program

Even though stainless steel is robust and reliable, it’s still susceptible to damage from unbalanced pool water.

To ensure your pool cover lasts and performs well, it’s essential to test and adjust your pool’s water chemistry regularly. However, Remco also offers additional servicing help to our customers via a Preventative Maintenance Program (PPM).

The best way to extend the lifespan of our automatic pool covers, our PPM occurs once a year by Remco technicians. This proactive servicing is often conducted during autumn and winter, providing peace of mind for effortless summertime swimming.

If you want to learn more about Remco’s PPM, please call our head office at 1800 652 962.